Executive Summary

Pillar 7: Environmental Regulations and Permitting presents strategic policies to imminently capitalise on the benefits of biogas production, ensuring plants are designed, developed and operated in a way that prioritises environmental protection.

This pillar outlines several revolutionary solutions aimed at improving the permitting process. For the biogas industry to grow at the pace required to meet these global challenges, environmental permitting processes must be streamlined and expedited. It is the responsibility of governments to adopt and implement these recommendations, ensuring that biogas development aligns with both environmental protection and the broader goals of sustainability.

Conclusion

A more efficient permitting framework would reduce delays, encourage innovation and facilitate the deployment of biogas technologies while maintaining strong environmental safeguards. These recommendations, when incorporated into government regulations, will revolutionise the way the industry is scaled up in a sustainable manner.

PILLAR 7: Environmental Regulation and Permitting

Introduction

The global shift towards sustainable waste and energy solutions has placed anaerobic digestion (AD) at the forefront of green technology. AD holds significant promise for reducing greenhouse gas emissions and creating a circular economy. However, the widespread adoption of this technology is often hindered by complex and fragmented regulation and permitting processes that vary across regions and jurisdictions.

To address these challenges, it is crucial to establish clear regulation across a variety of types of facilities as well as a standardised and viable permitting process that can be universally applied.

Such a regulatory framework will offer a clear and streamlined permitting process geared towards ensuring compliance and environmental protection while maintaining high standards of quality and safety in the industry. It must strike a balance between protecting the environment and not having too many legalities preventing the construction of facilities.

I. REGULATION

7.1. Take a risk-based approach to environmental regulation

The environmental risk posed by an AD operation will depend on a range of factors, such as:

- individual plant location and context

- plant design and specification

- plant processing capacity

- intended feedstocks to be processed, and

- final products to be created.

Sites will present differing degrees of risk to the local environment, and any regulatory framework must take this varying risk into account. A risk-based approach to regulation that incorporates a hierarchy of different regulatory tools for different risk levels should be adopted.

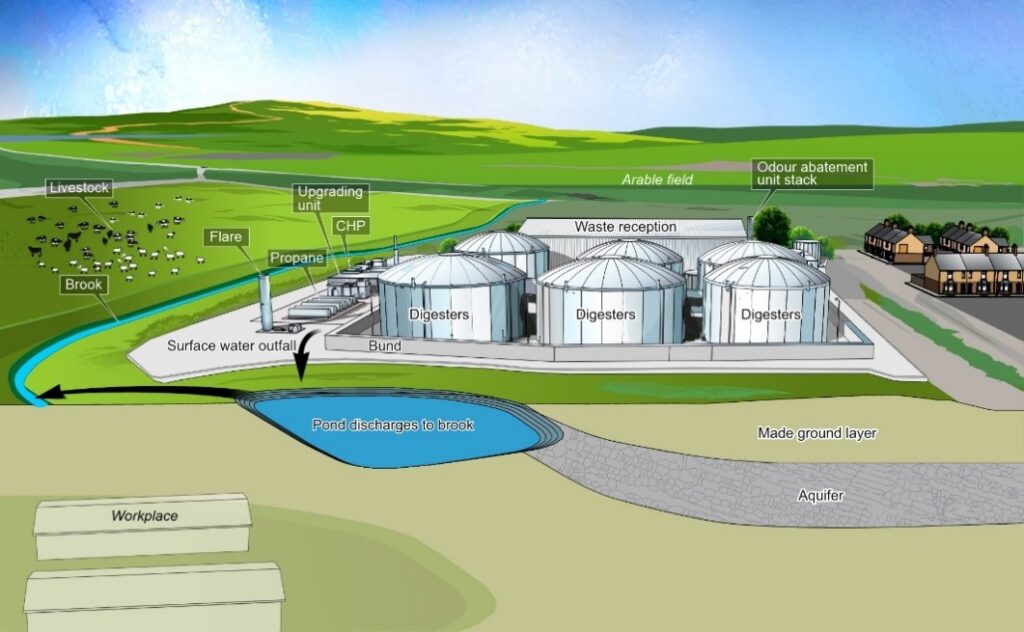

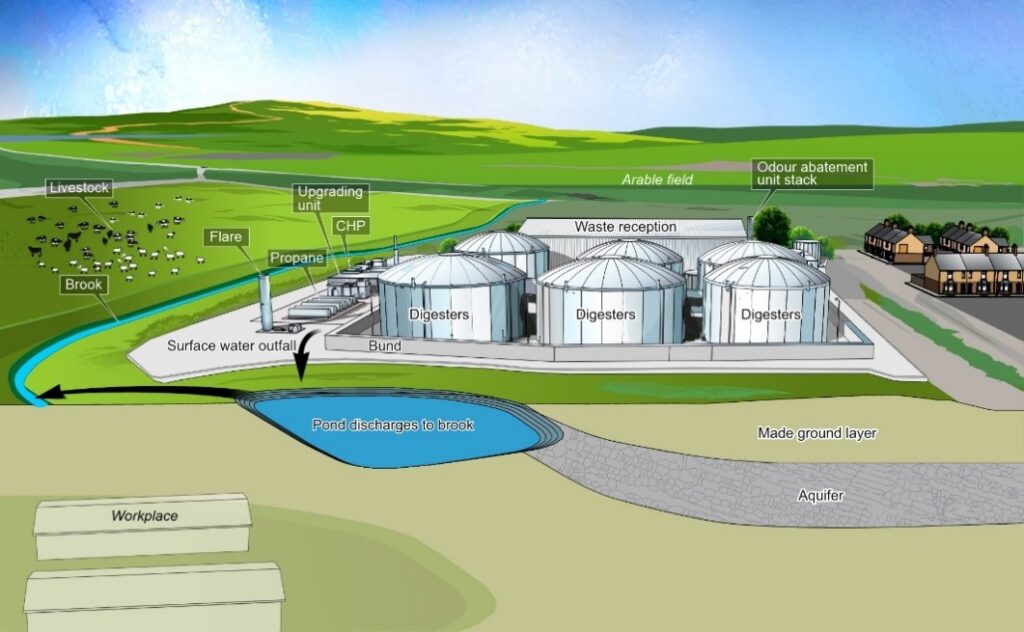

The source-pathway-receptor model is widely used for the evaluation of environmental risk and can be used as the basis for determining the risk potential of different plants in different locations. A conceptual model of the operation in a given environmental context allows the identification of potential pathways of pollutants to environmental receptors and evaluation of the level of risk.

Figure 1. Conceptual Model Showing Potential Sources Pathways and Receptors

Examples of aspects that must be considered when applying the source-pathway-receptor approach to assessment of environmental risk are outlined in sections 7.1.1–7.1.3.

7.1.1. Sensitivity of the location/receptors

- How far is the plant from people’s houses, workplaces or other sensitive receptors, such as schools, daycares, places of worship or medical institutions?

- How far is the nearest stream, and is the water downstream used for any other purposes, such as drinking water or fisheries?

- What is the underlying geology and groundwater status, and are there any wells, boreholes or source protection zones in the area for drinking water for people or livestock?

- Are there any sensitive wildlife species or habitat sites nearby?

- Are there wetlands nearby that host important species?

- What is the surrounding land use and topography/gradients?

- What is the expected future development in the area?

- Is there livestock in surrounding fields?

- Are there any existing air quality issues in the area?

- Are existing traffic routes congested or restricted?

7.1.2. Scale and nature of the AD activity proposed

- What feedstocks will be processed, and in what quantities?

- Will food waste be processed, and will packaging need to be removed?

- What will be the processing capacity of the plant?

- What is the storage capacity for feedstocks and digestate processing on-site at any one time?

- What is the storage capacity for final product on-site? What off-site storage is required?

- Is there a proposal to take water from a groundwater well or stream to use in the plant?

- Is there a proposal to discharge surface water into a nearby stream or via an infiltration gallery?

- How will the biogas produced be used or treated? How will it be stored?

- What chemicals will be used and stored at the site?

- Will the final digestate be separated into two fractions and how will each be handled? If no separation is proposed, how will digestate be stored?

7.1.3. Measures in place to prevent releases to the environment

- Are suitable and sufficient infrastructures, such as liquid storage and process tanks with secondary containment, in place to ensure the effective containment of any uncontrolled releases?

- Have drainage systems been designed to contain contaminated run-off or effluent from processing, and to separate clean and contaminated run-off?

- Is the site equipped with an emergency back-up flare for management of excess gas or off-specification gas?

- Are below-ground structures containing liquids fitted with leak detection systems?

- Are stacks on engine, boilers, generators or abatement units at a height to achieve dispersion?

- Are tanks fitted with pressure relief systems?

- Are pasteurisation facilities provided for sanitisation of digestate and feedstocks?

- Is stock-proof fencing installed to prevent access by livestock?

- Is the overall site secured and safe?

An effective framework for industry regulation must clearly outline the requirements and process for achieving permission or permits.

There must be an established, consistent and equitable approach that includes: engagement and consultation with relevant parties; transparency and accountability for decision-making; and a mechanism for appeals or mediation, if needed.

A risk-based framework will allow the regulator to apply proportionate regulatory controls to different levels of risk, and to focus the greatest efforts on sites that present greater risk. A framework that includes pre-determined assessment of risk can also allow a quicker and more efficient permitting process.

EXAMPLE

The US Environmental Protection Agency recommends this approach to conducting ecological risk assessments. 1

The UK Environment Agency takes a risk-based approach to environmental permitting. 2 3

7.2. Identify zones that may be suitable for biogas plants

Identification of ‘go-to zones’ is a recommended best practice measure to simplify permitting for priority biomethane projects. 4 5 Pre-assessed geographical areas are identified as suitable for development of biomethane infrastructure based on available feedstocks, access to grid connections and any other relevant local suitability factors. New projects in these areas are subject to quicker permitting due to the development zone having been pre-assessed in this way.

Commonly, zoning must be appropriate before applying for environmental permitting. Pre-assessed geographical areas designated as suitable for AD should be further determined through a risk-based approach. If zoning rules for given areas made this type of facility eligible, it would drastically reduce the siting efforts required of developers.

Creation of zones is discussed further in Pillar 8: Planning Policy.

EXAMPLES

In Columbus, Ohio, each parcel of land is zoned for a particular use, such as family housing, manufacturing, commercial or institutional. 6

A number of states in the US have taken the zoning approach to planning policy, including Pennsylvania, Tennessee and Ohio. 7

The French Urban Planning Code takes a zoning approach to planning policy. 8

7.3. Develop and implement a hybrid zoning and permitting matrix

It is clear that the zoning approach can have significant benefits in prioritising and facilitating completion of biomethane projects over short timescales, and it is recommended as best practice. A combination of this zoning approach linked to different types of permits for sites falling into different environmental risk locational bands would seem to be the most effective way of accelerating development, while also providing proportionate and necessary control for environmental risk. In reality, both components are necessary to expedite the development of more AD facilities more quickly.

7.4. Legislate overriding public interest

The presumption of overriding public interest is used to prioritise critical national infrastructure development, such as healthcare, transport, water and energy. Given the critical need for waste management and renewable energy projects, this approach is recommended to fast-track applications for biomethane projects and speed up the permitting process.

EXAMPLE

The Council of the EU has implemented measures to speed up the permit-granting process for the deployment of renewable energy projects. This framework includes a presumption of overriding public interest for renewable energy projects. 9

7.5. Determine which activities must fall under regulation

When establishing a regulatory framework based on the risk posed, clarity should be provided on which aspects or activities at an AD plant must be regulated.

7.5.1. Direct regulation

Determine which AD operations must be regulated and which will not, based on risk and national and local policy lead.

EXAMPLES

In the UK, AD plants must be regulated if the feedstocks processed are classified in law as wastes. 10 Where feedstocks are not legally classed as wastes, the AD process does not currently need to be regulated. Manures and slurries are defined as waste when processed in an AD plant, and so small on-farm plants processing animal manures and slurries fall under regulation, where large plants processing non-waste purpose-grown energy crops do not require regulation. In the UK, plants that process food wastes classified as animal by-products need additional controls and approvals to ensure that these materials are processed to the necessary standards. 11

In Ontario, Canada, plants that process food waste and are located in industrial zones are subject to an Environmental Compliance Approval issued by the local regulator that prescribes on-site activities. A threshold size is set at 1,000 tonnes per day: above that level an application needs an Environmental Assessment, which is a much more comprehensive and lengthy permitting process. On-farm AD, however, is exempted from Environmental Compliance Approvals if it is on agricultural land, and it can receive up to 50% off-farm biowastes to supplement agricultural materials. 12

7.5.2. Specific regulation

Determine if any activities associated with an AD operation must be regulated.

EXAMPLE

In the UK, emissions from medium combustion plant and specified generators are subject to specific regulation. 13 14 Where an AD operation processing wastes falls under direct permitting, any associated medium combustion plant, such as combined heat and power (CHP) engines, boilers or generators, are regulated under the same permit as the AD activity. Where an AD plant does not fall under direct permitting, then a permit will still be needed for operation of any associated CHP engines or boilers.

7.5.3. Digestate regulation

Determine if final digestate outputs from AD operations continue to fall under regulation.

Any regulatory framework must specify if the final digestate from an AD facility falls under regulation when it leaves the site for further storage and use in agriculture. The roles and responsibilities of the digestate producer and end user must be clearly defined. Digestate policy and regulation is further discussed in Pillar 4.

EXAMPLE

In the EU, digestate is regulated by Regulation (EU) 2019/1009 with clear distinction and requirements for digestate from fresh crops and digestate from feedstock other than fresh crop. 15

7.6. Set standards and requirements for permitting

It is crucial that the standards that must be met to achieve a permit are established and clearly communicated. This will allow plant designers and developers to build in the necessary controls at the planning and development stage and so enable successful permit applications.

Standards must be evidence based and presented in an accessible way to technology providers, developers and potential applicants.

Potential standards and controls that must be in place at the plant design and construction level to manage environmental risk from AD operations are as follows:

- secondary containment measures for liquid storage tanks 16

- design and construction standards for tanks and primary containment structures 17

- design and construction standards for manure, silage and digestate storage facilities 18

- drainage systems to allow separation of clean surface water and retention of contaminated drainage

- leak detection systems for below-ground structures storing liquids

- installation of pasteurisation systems

- installation of equipment that is specified to meet required limits on parametres for emissions to air, water, groundwater or land

- installation of infrastructure to allow management of unusual operational conditions, accident and incidents, e.g. flare for management of excess biogas, measures for managing foaming in digesters, lightning protection measures, fire risk management measures

- systems for containment and abatement of fugitive emissions, such as volatile organic compounds (VOCs) odours, noise, dusts and bioaerosols

- systems for process monitoring and control

- systems for gas leak detection and repair

- ystems for management of incidents, accidents and complaints

- staff training and competency standards.

The setting of technical and operational quality standards for the AD sector is further discussed in Pillar 6, which considers areas of operation that benefit from standard-setting.

EXAMPLE

The European Best Available Techniques Reference Document (BREF), the associated establishment of Best Available Techniques (BAT), and appropriate measures guidance for the waste treatment industry are applied to the biogas industry. 19 20

7.7. Establish a documented Environmental Management System

At an operational level, a documented Environmental Management System (EMS) must be established based on a source-pathway-receptor site risk assessment.

The EMS should specify the measures that will be implemented at the site on an ongoing basis to ensure that operations are carried out to minimise environmental impacts and comply with any standards or permit requirements.

An EMS must address permitting requirements such as:

- a clear statement of personnel roles and responsibilities for plant operations

- procedures for pre-acceptance assessment of feedstocks to determine their characteristics and inform decisions about suitability for processing, and handling and processing procedures when received

- waste/feedstock acceptance procedures for receiving material on-site

- standards for waste storage, handling and processing, including containment and maximum storage times

- operational process monitoring procedures for plant performance and emissions

- environmental accident, emergency and response plan, including incident and near-miss reporting and investigation procedures

- specific management plans for relevant identified significant environmental aspects, such as an odour management plan, noise management plan, pest management plan, fugitive emissions management plan and bioaerosols management plan

- an ongoing schedule of environmental monitoring, including leak detection and repair schedules, and potentially the monitoring of the status of receptors such as groundwater and surface water

- measures for managing environmental risk in the event of plant decommissioning

- provision for the management of residues arising from the process, e.g. packaging waste, spent carbon media, digestate

- monitoring of any ground or surface water abstractions undertaken for plant use

- a proactive maintenance schedule for plant and equipment

- a series of work instructions for site staff

- staff training-needs analysis, training schedules and records

- procedures for maintenance, review and update of the EMS, and for control and retention of documents

- a means of ensuring sufficient competence and resources will be available to support operations.

There will be additional management systems that must be set up to meet other potential regulatory requirements, such as health and safety and control of animal by-products. Measures for management of health and safety are further discussed in Pillar 9. 21

EXAMPLE

ISO 14001 – Environmental Management System provides a global standard to measure, manage and improve environmental performance. 22 This standard is widely used and recommended including in the US. 23

7.8. Use a hierarchy of regulatory tools based on risk

Providing a hierarchy of regulatory tools issued according to pre-assessed risk factors can achieve a proportionate regulatory framework and reduce the regulatory burden on operators. Prioritising effort in this way will also allow the regulator to focus their efforts on working with sites that are very large, complex, or close to sensitive locations where additional risk assessments and control measures may be necessary.

Examples of permitting options under these systems for plants presenting different levels of risk are detailed in sections 7.8.1–7.8.4.

7.8.1. General binding rules

General Binding Rules (GBRs) are a set of mandatory rules that cover specific low-risk activities. These low-risk activities are generally already well-quantified. If an operator intends to carry out an activity that is covered by GBRs, provided that the operator complies with the rules in full they are authorised and do not need to apply for any other permitting.

7.8.2. Exempt activities and registrations

Activities that are small-scale or low-risk are exempt from permitting. The limits of exempt activities are specified with respect to aspects such as location factors, maximum annual tonnages stored or processed, operating conditions and the type of material processed or handled. Some form of registration or low-level reporting is usually required. Exemptions may be free or chargeable, and if fees are applied they are typically much lower than for activities that require a permit. Re-registration may be needed periodically.

Generally, exempt activities are for smaller-scale operations that present low risk and would face barriers if going through a more comprehensive process.

EXAMPLE

The Scottish Environmental Protection Agency (SEPA) applies a permitting exemption to smaller-scale AD plants where the only waste inputs are agricultural or distillery wastes. 24

The Environment Agency of England and Wales provides a registration system for small scale exempt AD activities. 25 26

7.8.3. Standard rules permits

This is a prewritten permit for an activity that has already been pre-assessed via a generic risk assessment. The permit can apply to sites that fall within a given operational and locational design specification, and with subsequent pre-specified conditions for the management of risk. The standard rules permit has clear criteria for plants that can apply that fall within the parametres of the generic risk assessment, based on: materials processed; plant specification; location factors; annual throughput processing capacity; and feedstock types. There is a set application fee for all applications for a standard rules permit.

EXAMPLE

The Environment Agency in England and Wales has issued a series of standard rules permits for AD operations based on specific criteria and generic risk assessment. 27 28 These rules are presented below.

Locational Criteria for Standard Rules Permits for AD

The site must be a minimum distance from certain types of sensitive receptors. It cannot be within:

-

200m of the nearest receptor as measured from any combustion stack or stacks, unless the stacks are at least 7m high and the effective stack height of each stack is greater than 3m

-

250m of the nearest sensitive receptor where any further treatment takes place by composting digestate fibre in the open

-

500m of a site (within the meaning of Regulation 8 of the Conservation of Habitats and Species Regulations 2017, aligned to EU legislation) or a Site of Special Scientific Interest, including candidate or proposed sites, or a marine conservation zone

-

a groundwater source protection zone 1 or 2, or if a source protection zone has not been defined then within 50m of any well, spring or borehole used for the supply of water for human consumption (including private water supplies)

-

250m of the presence of great crested newts, where it is linked to the breeding ponds of the newts by good habitat

-

10m of any watercourse

-

50m of a local nature reserve, local wildlife site, ancient woodland or scheduled monument

-

50m of a site that has species or habitats of principle importance (as listed in Section 41 of the Natural Environment and Rural Communities Act 2006) that the Environment Agency considers at risk to this activity; these are also often referred to as priority habitats and species

-

a specified air quality management area.

7.8.4. Bespoke permits

Bespoke site-specific permits are written to specify controls needed for a particular site, based on a site-specific risk assessment that considers the specific plant location factors and proposed plant design and operations. This type of permit is applied when the standard rules criteria cannot be met. This is the expected pathway for larger-scale facilities and/or facilities that process more complex feedstocks or that are in closer proximity to sensitive receptors.

The application fee for a bespoke permit is typically more costly than a standard rules permit as they usually take more time to assess, are of a more specialist nature, and are dependent on the supporting information that must be submitted. An operator can apply for a bespoke permit that includes a range of different activities which can then all be regulated under one permit; for example, the operation of an AD process, operation of a medium combustion plant and the discharge of effluent to surface waters can be under one permit.

EXAMPLE

The Brazilian State of Paraná has developed a framework for AD permitting that includes permits for different feedstocks and different scales of activity, and includes permits for the planning, installation and operational phases of a project under a single permitting framework. 29

7.9. Develop end-of-waste position statements/quality protocols

Where feedstocks processed in an AD plant are regulated as wastes, the end-products from the process are also regarded as wastes until it is demonstrated that they have been fully recovered and met legal end-of-waste criteria. 30 End-of-waste position statements are helpful ways of enabling operators to understand and demonstrate the requirements for end-of-waste, which in turn helps to reduce the regulatory burden and encourage the recovery of valuable end-products.

EXAMPLE

The Environment Agency of England and Wales and Northern Ireland have issued quality protocols providing a clear national end-of-waste position and criteria for digestate and biomethane. 31 32

The EU fertiliser regulations make provision for an end-of-waste position for biofertilisers, including digestate. 33

II PERMITTING

The primary objectives of establishing a viable permitting process for AD are:

Streamline the permitting process:

- reduce the time and costs associated with obtaining permits by creating a clear and efficient pathway for project developers

- simplify the documentation and submission requirements to make the process more accessible to a broader range of stakeholders

Ensure regulatory compliance:

- develop a standardised process that aligns with the regulatory frameworks of different jurisdictions, ensuring that projects meet all necessary legal and environmental requirements.

- facilitate ongoing communication and collaboration with regulatory bodies to keep the process updated and relevant.

Facilitate the involvement of accredited persons:

- incorporate accredited persons and specialised consulting firms into the process to provide expert oversight and validation, ensuring that projects adhere to the highest standards of quality and safety, and to bring additional resources into the permit review function

- establish clear criteria for accreditation and a system for continuous professional development and accountability.

Promote the adoption of AD:

- encourage the adoption of AD technology on a global scale by making the permitting process more efficient and transparent

- contribute to the growth of renewable energy infrastructure by supporting the development of biogas plants worldwide.

Currently, the timeline for applying for and receiving permits is a key challenge in the biogas industry. Developers, who are at the forefront of building these plants, incur additional risk when there is uncertainty about if and when a permit will be granted.

There are a number of existing risks already being managed by biogas facility developers, including:

- regulatory risk: changes in regulations and standards can affect design, construction and operations. In an area where regulation is relatively new, changes to regulation can adversely affect business outcomes.

- feedstock risk: with feedstocks in high demand, and with a need to arrive at optimal logistics to supply a plant with a suitable mix, this remains a significant business case risk. The ability to tie up feedstocks in the long-term accentuates this risk over time.

- off-take risk: the ability to monetise renewable electricity or renewable natural gas is highly dependent on local and non-local incentives, programmes, cap-and-trade methodologies and the complexity of the buyer network domestically and internationally.

- technology risk: while technology is mature and recognised in the space, the integration of disparate technology components (digestion, biomethane or electricity production, wastewater management, digestate production, etc.) creates a significant need for appropriate consideration of holistic design.

- stakeholder risk: biogas plants will receive materials that may be of concern to local populations and municipalities. Stakeholder management can be a key risk point for developers if the host community is not in favour of the project or programme.

As already mentioned, developers have incurred risk related to uncertainty about if and/or when they will receive permits. This is an added burden that multiplies the risks noted above and jeopardises the viability of biogas projects.

Biogas developers typically put forward substantial monetary outlays to find and secure projects and feedstock, purchase land or rights to land and then engage in the permitting process. Without a timely permitting process revenue is further delayed, causing developers to look to the even longer term for expected returns. This adversely affects business cases and slows down the adoption of biogas plants.

Timelines for receiving permits varies globally from months to years. There are two components to streamlining permits:

- assisting regulators with support mechanisms that allow regulators to consider and approve permit applications in shorter periods of time. This viable process can include the promise of expedited service (shorter review timelines) and/or the use of accredited persons to assist in the review process.

- development of a comprehensive permitting template that would be used by developers to make their submissions, taking into account local codes, standards and regulations, and that would further allow regulators to receive complete submissions for their internal review and/or for review by accredited persons.

These two items are separate but related and will be discussed in greater detail below. Expedited service and accredited persons are expected to be most useful in shortening review timelines when paired with a permitting template, and vice versa. Inextricably linked, these become essential components of a system.

7.10. Establish the viable process

Regulatory/permitting agencies across the world have multiple challenges and provide approvals for multiple types of infrastructure. The expansion of biogas, and the necessity to develop biogas projects at an accelerated rate to deal with climate issues, adds another element to an already complex set of tasks. Globally, regulators can be divided into the following general categories:

- Regulators with no previous experience in biogas. While biogas plants exist in number in Europe, there are parts of the world where biogas must develop, such as parts of Asia, the Americas and Africa, where proportionately little experience in this area prevails. As a result, guidance for developers is sparse and the ability of regulators to review applications is constrained by a relatively thin information and experience set, leading to long timelines and permitting uncertainty.

- Regulators with some experience but constrained resources. While there are parts of the world where biogas permits have been issued in number, and experience does exist, regulators are busy with, among other things, the infrastructure needed as a whole for the energy transition. Most of this infrastructure is still relatively new, and includes onshore/offshore wind, hydrogen, carbon capture projects, battery energy storage systems, new nuclear, small modular reactors, etc. The burden on regulators continues to increase, at times without proportional staffing to allow permit applications to be considered promptly. In these cases, the workload for permitting staff increases and timelines are delayed accordingly.

- Regulators with experience and unconstrained resources. While this would be optimal, the likelihood that this condition exists is slim. In reality, most regulatory bodies fit into category 1 or 2. However, even in the case where resources are present and regulators have experience with biogas plants, timelines may not be optimal and can be improved.

The extenuating factor in this discussion is that permitting is regional. Permits for biogas plants are not generally issued at the national level, but are done so at the state, provincial or municipal level. This creates a patchwork of different sets of experience and resource to accommodate permit applications from developers, as well as an inconsistency in the expectations of those applications across jurisdictions. This is a risk factor for developers and an impediment in the development of biogas plants.

As part of the viable process discussion, two options are presented as solutions to experience and resource constraint:

- Expedited service: the ability to accelerate permitting timelines by offering developers a shorter, defined review period in exchange for higher permitting fees. With respect to the types of regulators noted above, this element would help each of these categories, although it is noted that regulators with limited experience or constrained resources cannot readily offer this option without additional support. Regulators who have issued permits routinely in the past and who do not have resource constraints may benefit from this element most readily, driving down permit review times.

- Accredited persons: generally works as outsourced support to regulators who either do not have the knowledge and experience in biogas, and/or do not have the resources to provide review in an expedited timeline. This would mainly apply to category 1 and 2 regulators, as noted above. It is supposed that the use of accredited persons (external third parties) to review permitting packages would be the single most-enabling feature allowing regulators in categories 1 and 2 to be able to provide an expedited service.

Expedited service and accredited persons are discussed in sections 7.10.1 and 7.10.2.

7.10.1. Expedited service

One of the cornerstones of the viable permitting process is the introduction of an expedited service. This service offers a fast-tracked permitting process for applications that meet specific criteria, ensuring a shorter, guaranteed timeline for review and approval. The expedited service is particularly beneficial for time-sensitive projects that require rapid deployment.

Eligibility criteria

- To qualify for an expedited service, applicants must use a comprehensive permitting template (see section 7.11) that has been developed as part of the global permitting certification scheme. This template ensures that all necessary information is provided in a clear and organised manner, reducing the potential for delays caused by incomplete or unclear submissions.

- Clients opting for the expedited service must be willing to pay an additional fee, which justifies the accelerated timeline and the additional resources needed for the fast-tracked review. In return for this additional fee, the regulator can offer a predefined and shortened review period. The fee allows the regulator to pay for either the prioritisation of internal resources or the retention of accredited persons.

As noted, timelines for submission and permit approval for biogas plants can range from months to years. Some regulators will offer guaranteed comment periods if permit applications are complete, with the caveat that completeness can be somewhat subjective.

Given the urgency around biogas plants, a target review and comment period, pending use of the permitting template and providing the information required in that template, would be in the order of three months. This allows the regulator to provide the required technical review and issue comments. Given that a permitting template would be used, gaps in information provided by developers are expected to be minor. As a result, a reasonable time period to address regulator comments, issue draft approvals and negotiate final approvals is in the order of one month under this expedited review framework.

The total time from permit submission to the final permit being issued is therefore four months. A period of four months is a dramatic reduction in total time for the review and issuing of permits for biogas plants compared to current timelines, and it represents a significant element in de-risking biogas projects.

The additional fee required by the regulator will be a function of the additional resources required to expedite the review. This may require using more internal resources on a project file, or possibly increasing the workforce. It may also require consideration of administrative requirements beyond those typically applied. Each of these considerations would be used to calculate the additional fee necessary.

Where the regulator is not able to process the permit applications in-house, the additional fee would, at the minimum, cover the cost of retaining accredited persons, in addition to any other administrative costs applicable.

While additional fees may be substantially more than standard permit fees, this is balanced against the cost of delays to implementing biogas projects. These projects do not generate revenue until they are permitted, designed, constructed and commissioned. For every week or month of delay, revenue is foregone. It is expected that reducing permitting timelines from years to months would provide enough value to justify the additional fee.

7.10.2. Accredited persons

The provision of an expedited service, as noted above, relies on the physical ability, bandwidth and experience to review and issue permits in the timeframes noted.

For regulators who have both the experience and resources to do so, an expedited service remains an important commitment that allows for the prioritisation of resources to achieve the timelines noted.

Where either experience or resource is insufficient to provide an expedited service, the regulator needs additional support. Using external resources has the following benefits:

- For regulatory bodies that may lack the in-house capacity to handle the increased demand for expedited reviews, the option to collaborate with accredited persons or specialised consulting firms is invaluable as a way to offer an expedited service.

- External experts, who are vetted and accredited based on their expertise, provide the necessary technical capacity to support, validate and approve applications within the shortened timelines.

- By outsourcing to expert bodies with a deep understanding of regional and municipal by-laws, the risk associated with approving complex projects is significantly reduced, ensuring that projects meet all regulatory requirements before approval.

Accredited persons would be familiar with the permitting template, have trained professionals able to review applications according to that permitting template and would essentially act as an arm of the regulator to do this work. While this is a form of outsourcing, in reality it provides additional bandwidth and capability to a regulator, rather than a replacement, which augments the regulator’s ability to work. The final permit would still be issued by the regulator, compliance during operations would be assessed by the regulator, etc.

In order to drive credibility in this process, accreditation and accountability of the accredited persons must be pre-established. Regulators should be able to select an accredited person from a small group that have demonstrated the ability to do this work to the highest standards. Sections 7.10.2.1–7.10.2.5 outline important considerations.

7.10.2.1.

Criteria for accreditation

The criteria for accreditation include: demonstrated expertise in the review of regulatory submissions across the space of infrastructure; demonstration of capability and resources to accommodate multiple permit reviews; and a proven track record of successful project evaluations.

7.10.2.2. Ability to interpret the permitting template

The permitting template is a key component of allowing the use of accredited persons to streamline permitting and to increase the capability of regulators. The ability of bodies wishing to become accredited persons to understand and interpret the permitting template for biogas projects is a key determinator of suitability.

7.10.2.3. Ongoing accountability

Accredited persons or firms will be subject to regular audits and reviews to maintain their status. This ensures that they continue to meet the high standards required and stay updated with the latest regulatory changes and industry best practices.

7.10.2.4. Quality assurance

Accredited persons must demonstrate that they work according to a prescriptive quality control and assurance programme that further speaks to confidentiality, document control and auditable processes.

7.10.2.5. Partnership development

Regulatory bodies should establish partnerships, as necessary, with leading consulting firms and accredited individuals to create a pool of available experts for expedited services. This network will enhance the overall efficiency and reliability of the permitting process.

A viable means of developing accredited persons is for an independent organisation to undertake this process. This would require the assessment and ultimately accreditation of these bodies, and the nomination of a small number that would be available to regulators. It is expected that regulators would conclude commercial agreements with accredited persons to provide the required services, and that this commercial agreement would establish the additional fee that regulators would apply to applicants.

7.11. Permitting template

As noted, the ability to provide expedited service and to involve accredited persons in the review process is predicated on standardisation, to the extent possible, of the applications. While it is not possible to standardise the full extent of permitting packages, given the differences in regulations, codes and standards around the world, there are elements that can be standardised in order to drive efficiency.

As noted, permitting timelines for biogas plants can range from months to many years. This is simply the timeline for regulators to review and approve. Additional time is required to submit the application in the first place. The challenges here are twofold:

- For developers, the requirements for submitting permit applications change from one jurisdiction to another, and the local standards, codes and regulations also change. While local factors such as standards, codes and regulations cannot be changed, the requirements for a package can be streamlined and made into a template model so that developers see the same basic requirements in any jurisdiction. This means that developers will not have to create a new application from scratch in every jurisdiction; they will simply need to overlay the local regulations and standards onto a package that is common globally.

- For regulators, in some cases there is little knowledge of or precedent with biogas plants. In this case, applications are made without being able to express to developers what must be submitted, leading to a protracted process. In the situation where each regulator has their own process and develops their own template, timelines in aggregate throughout the world are extended, as each regulatory body ‘reinvents the wheel’.

The purpose of a permitting template is very simple. It allows developers to consistently use a comprehensive common and understandable template for making submissions. It also allows regulatory bodies to receive submissions that are complete, with comprehensive information that addresses the fundamentally important issues related to a biogas plant.

While permitting templates can greatly reduce the time for developers to submit applications and for regulators to review them, there are important local considerations.

Templates may lay out the essential information that is required for a comprehensive permitting package in a logical order. If the information requested is provided, then a complete package is sent to a regulator for review. However, regulations, codes and standards will potentially differ between jurisdictions. The template will point a developer to finding those local regulations, codes and standards, so that the package is made consistent with those all-important local requirements.

Sections 7.11.1–7.11.12 provide a form of permitting template with guidance on the type of information that would need to be provided for each section.

7.11.1. Project overview

A short narrative description of the project, indicating location, capacity and objectives. Define ownership of the land.

7.11.2. Site location, plan and description

Figures showing project location generally and in relation to local water bodies, roadways and other topographical features. Provide a geological and topographical overview of the site and context relative to inhabited areas.

Provide a site plan for the facility, showing the location of the facility and ancillary components (weigh scales, gas processing, tankage, processing building, storage areas including lagoons, wastewater treatment, odour control and release points, truck unloading areas, administrative areas and parking locations, etc.) on a figure that clearly outlines the extent of the owned/leased property.

7.11.2. Land use and confirmation of planning compatibility

Local zoning or other planning-related guidance and documentation demonstrating that the biogas plant conforms to local requirements. State the zoning of the land. Show compliance with local ordinances, including how the site and facility comply with capacity, height, setbacks, area coverage and other restrictions.

Provide demonstration of compatibility with other local requirements, such as airport authority limitations, conservation areas, wetlands, heritage areas, etc.

Information needed: local site plan and zoning designation and by-laws defining allowable on-site developments. Information on other regulatory stakeholders, such as airport authorities, conservation authorities, special-purpose environmental feature regulators, etc.

7.11.2.2. Stakeholder pre-consultation record and going-forward plan

Record of all stakeholder consultation undertaken to date with local stakeholders, host community, municipalities at lower-tier or upper-tier levels, state or provincial bodies, non-governmental organisations (NGOs), Indigenous peoples and regulators.

Information needed: map of all pertinent stakeholders that would have an interest in the site and facility.

7.11.2.3. Receptor description

Provide a figure with clearly labelled distances from the site to residential and other sensitive receptors (places of workshop, daycares, schools, etc.). Also define proximity to water courses, wetlands, depth to groundwater, proximity to livestock or sensitive wildlife habitats, archaeological features, heritage buildings, etc.

Information needed: mapping of receptors, including understanding how ‘sensitive receptors’ are defined locally and what this term includes.

7.11.2.4. Vehicle traffic plans

Demonstrate how organic materials will be transported on local roadways to access the site and how traffic movements will occur relative to the site plan. Provide an estimate of peak and average traffic ingress/egress at the site.

Information needed: arterial maps, local traffic and load restrictions, seasonal or otherwise.

7.11.3. Technical description

7.11.3.1. Plant design and layout

Define the capacity of the plant and show the layout of the plant and transit and flow of materials through the plant, whether liquids, gases or solids. Provide figures that clearly illustrate each of the main functions of the plant: material receipt; pre-processing, blending and storage facilities; buffer tanks; main digestion tanks; digestate management systems and storage elements; biogas handling and flaring equipment; energy tie-in locations; wastewater management and tie-ins; laboratory and testing facilities; administrative areas, etc.

Note utility connections such as the availability of potable or well water; the availability of sanitary sewers; the location of surface water outfalls; and the location of gas and electrical tie-ins. Provide calculations demonstrating that the existing or planned utility tie-ins can accommodate the requirements of the facility.

Information needed: pertinent data about existing and intended utilities and availability, and confirmation from utilities that sufficient capacity is or will be available.

7.11.3.2. Mass, liquid and energy balances

Provide mass, liquid and energy balances for all flows being managed by the facility. Include process flow diagrams for the facility. Provide an accounting of all chemicals being used at the site and all ancillary materials that may be generated, such as spent medias or waste oils.

Information needed: design information sufficiently ahead of time.

7.11.3.3. Liquids, solids and gases management

Demonstrate through narrative description how liquids, solids and gases are managed throughout the plant. Indicate key equipment, processing rates for key equipment, storage facilities and the ancillary key equipment required for the system to function. Tie-in to process flow diagrams, mass balances and organic load rates applicable.

7.11.3.4. Life, health and safety design

Provide figures and narrative text demonstrating monitoring and alarm systems for the facility, how employees, including those operating rolling stock, are protected from hazards. Define air exchange rates throughout the facility and how they are compatible with creating appropriate local health and safety conditions.

Information needed: local life, health and safety regulations; plans and local ordinances that define specific minimum requirements for on-site safety, for access for emergency vehicles; and any other pertinent interventions. Local construction or building code that specifies life/health/safety requirements. Local safety authority specifications for compressed and combustible gases, setbacks, etc.

7.11.3.5. Visual Impact

Provide figures, preferably 3D, showing how the facility will orient as it pertains to sensitive receptors, roadways, etc. Include any embankment, grading or other landscaping features meant to integrate the facility into the local landscape. Clearly define vertical infrastructure (stacks, tall buildings, etc). and how it is viewed from adjacent areas.

7.11.3.6. Feedstock summary and receipt rates

Quantitatively and qualitatively define anticipated feedstocks that are the subject of the permit. This includes expected annual and daily averages and peak quantities of each feedstock intended for processing at the facility. Provide ranges of tonnages of feedstock as necessary and how these tonnages will comply with a total tonnage estimate for the permit.

Indicate daily and weekly receipt rates for each feedstock, with ranges as appropriate.

Information needed: characterisation of feedstocks from feedstock suppliers.

7.11.3.7. Storage volumes and capacity

Quantitively detail the amount of storage infrastructure on the site in a plant layout, including intermediary storage tanks, final storage tanks, sumps, lagoons, processing vessels, etc. Indicate chemical storage locations and volumes.

This further includes storage of outputs, including residuals and digestate, condensates, wastewaters, contact waters, etc.

Generate a clear table of storage volumes by function of the plant and what these storage vessels will contain.

Information needed: environmental regulations pertaining to the storage of liquids in tanks, lagoons, etc.

7.11.3.8. Storage design and secondary containment system

Indicate the design of storage vessels, including sumps, tanks, lagoons, etc. Indicate materials of construction, physical configuration, pressure relief systems, how headspace gases are managed – either through biogas or odour abatement systems – and monitoring systems.

For all liquid storage vessels, provide the design of the secondary containment system to prevent leaks and impairment from catastrophic loss, through double-walled systems, area grading, secondary containment , etc. Clearly indicate how impounded secondary containment volumes would interface with surface water control.

Information needed: code restrictions, secondary containment guidelines relative to individual storage vessel and aggregated storage volume containment, and interface with surface water systems.

7.11.4. Process description

Provide piping and instrumentation diagrams with a process narrative of the plant. Define any pasteurisation steps occurring at the site and the temperature control regime for AD.

7.11.4.1. Energy generation and management

Indicate the energy generation scheme for the facility, identifying biogas used for electricity or biomethane production, or other. Indicate self-consumption volumes for the facility and expected exports to grids (direct connection points) or by virtual pipelines (indirect connection points, required transport to end consumer). Demonstrate backup systems for energy management for biogas management, such as flares or thermal oxidisers, along with capacities.

Information needed: environmental requirements for biogas management and backup systems, electrical grid interconnection requirements, natural gas grid interconnection requirements, vehicle regulations relative to transporting compressed gases.

7.11.4.2. Residuals and digestate management

Provide specific indication of how residual wastes will be managed on-site and how often they will be transported off-site. Indicate receiving bodies and appropriate licence s for those receiving bodies.

Provide a complete digestate management plan in terms of storage on-site, expected export off-site throughout the year, off-site storage locations for digestate, and expected final use of digestate (on land, etc). Define any additional digestate management steps, such as dewatering (including how centrates and filtrates are managed through on-site wastewater treatment and expected quality criteria), composting, drying, pelletisation or pyrolysis. In all cases, define the final-use options for the expected materials, as well as storage mechanisms on-site. Include the expected quality of digestate to be exported against relevant regulations, including for emerging contaminants such as PFAS (per- and polyfluoroalkyl substances also known as “forever chemicals”).

Information needed: environmental regulations relative to disposal or re-use of residual wastes (landfilling or energy-from-waste). Digestate management guidelines, nutrient management plans locally, and digestate quality specifications for liquid or solid digestate. Investigation of emerging contaminant allowable levels.

7.11.4.3. Surface water and groundwater management

Define expected volumes of surface water to be managed and how surface water will be storage on-site before discharge, how much surface water will be used in the facility, and how contact waters with impaired surfaces, such as roadways for incoming waste trucks, will be handled. Provide an interface calculation with secondary containment to show how secondary containment can be provided even during peak storm events. Indicate what, if any, discharge structures are required to impound surface water before discharge to the natural environment. Include monitoring plan for surface water.

Provide data regarding groundwater levels and quality, expected groundwater extraction rates, protective features, such as impermeable surfaces designed to minimise impact on groundwater quality, and ongoing monitoring systems designed to measure groundwater quality.

Information needed: hydrogeological requirements around pre- and post-development stormwater volume management, including stormwater quality specifications for discharge. Pertinent stormwater design specifications maintained by regulation, and characterisation of receiving water body. Regulations regarding allowable groundwater extraction volumes, including quality expectations for groundwater systems.

7.11.4.4. Wastewater management

Define how wastewater and process water will be managed on-site, whether through re-use in the process, treatment to a quality sufficient for discharge to sanitary sewer, or treatment to a level for release to the environment. Provide a specific process description of the wastewater management system, including all possible inputs, such as process water, contact waters, centrate, filtrate, condensate. If off-site transporting is proposed, establish a schedule for shipments and a description of the receiving bodies.

Information needed: specifications for quality of wastewater discharged to sanitary sewer (locally regulated ) and confirmation that the service is adequate. Similar specifications for discharge to natural environment.

7.11.4.5. Air, odour and noise management

Define air emissions of solids (dusts, etc.), aerosols and trace gases from the site and demonstrate through dispersion or other modelling that these emissions comply with local health and safety regulations.

Provide an assessment of odour and noise potential at the site, from all functions of the facility. Indicate odour abatement systems, such as biofilters or thermal oxidisers, and which streams of the available airflow will be treated through them, along with a calculation of expected odour at point sources. Define point sources based on flowrate, height and location, and provide dispersion or other modelling as appropriate to estimate impacts at the property line and at sensitive receptors against relevant health, environmental or other regulations.

Provide an assessment of noise sources, their generation levels, and unmitigated and mitigated impacts at the property line against regulatory standards.

Information needed: health and safety air quality regulations and parametres for specific trace gases emitted by the facility (hydrogen sulphide, ammonia, etc.) at ground-level and/or at sensitive receptors or property lines. Definition of point of impingement. Odour regulators as applicable and odour thresholds at the property line and sensitive receptors. Allowable diurnal noise limits.

7.11.4.6. Lifecycle assessment

Provide an appropriate lifecycle greenhouse gas assessment of the plant, account for mass, liquid, gas and energy inputs/outputs on a kg CO2eq/tonne incoming mass basis. Use an appropriate accredited assessment tool with boundary definition per local standards or recognised international standards.

Information needed: a defined standard for lifecycle assessment, set locally and/or globally.

7.11.5. Environmental impact assessment

7.11.5.1. Baseline environmental conditions

Provide a record of baseline environmental conditions for the site, including surface water, soil, groundwater, airshed, noise and odour. This assessment will define the existing quality of environmental features at the site across all media.

Information needed: record of site condition information required by the local environmental regulator.

7.11.5.2. Risk-based assessment

Based on the expected emissions from the site, provide a risk-based assessment of impacts, in addition to the predicted impacts from modelling activities. Use an acknowledged local or international risk assessment framework.

Information needed: accredited, acceptable risk-based framework locally.

7.11.5.3. Mitigation plans and predicted outcomes

Depending on the results of the risk-based assessment, provide additional mitigation measures to reduce risk.

7.11.5.4. Monitoring

For all systems at the facility, provide the monitoring system for both the process and environmental management systems. This should define how key parametres (such as liquid levels in tanks or quality of water in groundwater wells, or odour abatement performance of biofilters, etc.) are monitored and the expected threshold regulatory and performance limits for the facility.

7.11.6. Safety and risk management

7.11.6.1. Hazard identification

Identify all physical hazards at the site, all combustible or otherwise hazardous areas related to fire, explosion, etc., and how these hazards are mitigated.

Information needed: local building and safety authority code definitions of hazards.

7.11.6.2. Emergency response plans

Define an emergency response plan relative to identified hazards and any other foreseeable hazards that may develop at the site.

Further define emergency response plans for any interruptions to external service, such as inability to export residuals, digestate, wastewater or energy vectors.

7.11.6.3. Health and safety plans

Provide a site-specific health and safety plan for the equipment and systems in place at the facility.

Information needed: local health and safety regulations for the specific industry or an analogous one as needed.

7.11.7. Stakeholder engagement plan

Generate various plans for going-forward stakeholder engagement, such as liaison committees or other consultation mechanisms that clearly demonstrate how engagement will occur during construction and operations.

Information needed: consultation with the local regulator to determine the minimum stakeholder engagement needed, then development of a plan in consultation with the regulator to account for local issues.

7.11.7.1. Consultation plan with local communities

Define a plan for immediate local stakeholders, residences and sensitive receptors, in terms of information dissemination, liaison committee meetings, townhalls, etc. Establish an outreach database of stakeholders that maps pertinent groups and individuals, including regulatory bodies, NGOs, and other interested parties.

7.11.7.2. Indigenous peoples consultation plan

Establish a specific engagement plan for indigenous peoples.

7.11.7.3. Complaints response and feedback plan

Define a complaints intake and response plan and how it will be articulated to stakeholders. This plan will have a clear set of contact information for lodging complaints, a process by which to assess and respond to complaints, and a reporting mechanism to alter processes as necessary to continually improve on-site processes.

7.11.8. Regulatory compliance plan

7.11.8.1. Statement of relevant regulations and standards

As noted in this template, provide a list of all pertinent regulations and standards and how often this will be updated.

Information needed: full scan of applicable local regulations, codes and standards that will inform preparation of the permitting application.

7.11.8.2. Ongoing regulatory monitoring plan

Define the process for how compliance will be assessed against the regulatory requirements noted above, contained in the final permit, managed and reported.

7.11.9. Site operations

While the above information is generally provided at the design stage, how the facility operates is crucial to its eventual success and must be integrated with design information and how it will be adhered to and made compatible with operations. While some of the following items are self-evident, others include more complexity.

7.11.9.1. Hours of operation

Clear statement of operating hours for each day.

7.11.8.2. Service area

Define the allowable extent of waste imports geographically, as per permit requirements.

7.11.9.3. Description of on-site operations

Provide a narrative description of on-site operations in terms of when various features of the plant will be operational. When will waste receipt occur relative to processing? Which processing components are continuous?

7.11.9.4. Environmental management system

For all environmental management systems noted in the design section, provide a narrative description of how these will be overseen from a data collection, data analysis and response standpoint.

7.11.9.5. Incoming waste inspection procedure

For the waste types noted, indicate how wastes will be inspected to ensure that contraries are not received. Define testing procedures for incoming feedstock, testable parametres and frequency of testing. Indicate if testing will be done on-site or off-site.

7.11.9.6. Outgoing waste and digestate testing procedures

Define how often digestate will be tested and against what parametres. Indicate if testing will be done on-site or off-site.

7.11.9.7. Liquids disposal plan

Define how liquids will be disposed on-site and how testing will be done for effluent liquids, including stormwater, against pertinent sewer or natural environment standards. Indicate if testing will be done on-site or off-site.

7.11.9.8. Dust, pest, litter, air, noise and odour

Indicate how testing will be achieved for demonstrating compliance with odour and air regulations and how inspections will be done in general to identify environmental nuisances caused by the facility and site. Provide plans for managing dust, pests and litter, including inspections and mitigation activities.

7.11.9.9. Energy management plan

Provide a narrative of how and in what form energy will be exported to grids or by virtual pipelines and how operations will accommodate any interruptions to export services. Indicate how biogas switching to back-up devices, such as flares or thermal oxidisers, will occur and how decision-making will be done in this respect.

7.11.9.10. Preventative maintenance plans

Provide preventative maintenance plans for all key processing and environmental equipment.

7.11.911. Site security

Define how the site will be secured, fenced and gated, and signed.

7.11.9.12. Site monitoring and inspection

Develop a comprehensive site inspection plan, including the frequency of inspections, reporting and response.

7.11.9.13. Complaint management

Define how the complaints response plan will be managed at the site level and a definition of how in-person complaints will be managed.

7.11.9.14. Staffing plan

Provide a full staffing plan, including the definition of plant manager, operations manager, maintenance manager, and all other staff required. Indicate how many operating shifts are relevant to the facility and how these will be staffed. Define a point of responsibility for regulatory compliance and for the inspections required to demonstrate compliance.

7.11.9.15. Staff training

Define how ongoing staff training will be provided, in what areas and to what staff.

7.11.9.16. Record keeping

Indicate how records will be kept, for how long, and how they will be presented as required to regulatory agencies.

7.11.9.17. Spills and fire management

Define a procedure for dealing with spills of liquid identified in the design sections. Provide a fire management plan, including monitoring and inspection and threshold criteria for alerting external emergency response personnel.

7.11.9.18. Emergency notification and response plans

Retain a record of agencies and other bodies that must be contacted in the event of an emergency and indicate where this will be kept.

7.11.10. Site closure plan

For the point at which operations cease, provide a plan for how operations will be wound down and how infrastructure will be managed going forward.

7.11.11. Financial assurance

Where applicable, define financial assurance as an instrument with sufficient security, protective of premature shut-down of the facility. Provide calculations about processing and storage volumes, and of what funds will be necessary to clean out the facility during unintended premature shut-down, or during final shut-down.

7.11.12. Turn-over plan

Provide a turn-over plan that addresses ending operations and, if applicable, a restart plan for a new operator.

7.12. Streamline implementation of the viable process and permitting template

House the permitting template on the government website so it is readily available to regulators and developers. As part of consultation, agencies would drive awareness of the permitting template and how it would be used to expedite approvals. The government website would also house a list of accredited persons that regulators could use to supplement their resource base in reviewing permit applications.

7.12.1. Implementation roadmap

The following steps outline the implementation of the viable process:

- Develop the permitting template: Collaborate with industry stakeholders to create a detailed template that meets regulatory requirements across various jurisdictions.

- Establish the accreditation system: Define the criteria for accrediting external experts and create a robust system for maintaining their accreditation.

- Roll out the expedited service: Launch the expedited service, including the fee structure and communication channels between clients, regulatory bodies and accredited experts.

- Monitor and refine: Continuously monitor the effectiveness of the expedited service and refine the process based on feedback and evolving industry needs. This would include development of a traceable process that allows submitters to track their application and to have sight of the decision-making process. Further, an appeals process should be developed following a final decision, indicating what areas can be appealed.

By establishing a viable permitting process that includes an expedited service and external expertise, the Global Biogas Regulatory Framework will significantly accelerate the adoption of AD technology. This will result in faster project approvals, higher quality standards and a more robust renewable energy infrastructure certified worldwide by the ADCS-Intl.

7.13. Develop a single environmental permitting framework

Develop a single, streamlined environmental permitting and compliance framework that will be easier, quicker and cheaper for businesses to understand and comply with, and for regulators to apply and enforce. Under a single framework, all aspects that must come under regulation can be addressed by a single permitting process.

A series of different permissions may be needed for an AD development in addition to an environmental permit, e.g. planning permission, approval for processing of animal by-products, biogas combustion, building permit. Where this is the case, the various application processes should at least avoid duplication of effort by the applicant and the regulator and avoid conflicting requirements between the processes. The applications would ideally be done through a single combined application process: a ‘one-stop shop’ for biomethane permitting.

EXAMPLES

The Biomethane Industrial Partnership report on accelerating biomethane permitting recommends the implementation of a one-stop shop for biomethane permitting as best practice for achieving an accelerated process. 34

The Environment Agency in England and Wales has established a single framework that is outlined in a publicly available core guidance document. 35

See the example of the Brazilian State of Paraná at 7.8.4.

7.14. Define maximum application waiting and determination times

Provide clear information to applicants about expected waiting times for permit assessment and issue. Include a mechanism for requesting additional information, if needed, at the start of and during the application process, with clearly stated maximum statutory determination timeframes for issuing permits once a complete application is accepted.

Provide sufficient resources to meet the stated maximum statutory determination times through the adequate funding and provision of sufficient suitably skilled staff. Provision should be made for development of resources in line with industry growth, so that maximum determination time for permits can be maintained throughout growth periods.

EXAMPLES

BIP Europe have developed a factsheet outlining best practice for accelerating biomethane permitting. 36

The Environment Agency in England and Wales has set up a means of submitting complex or novel permit applications in stages according to an agreed timetable. 37

7.15. Provide a process for appeals

Provide a system of appeals following any final decision or outcome for both developers and stakeholders. Be clear and specific about what matters can be taken to appeal and have a streamlined public enquiry period. As with permit determination, the appeals procedure should have clearly defined deadlines or a maximum number of instances.

EXAMPLE

The BIP Europe factsheet on accelerating biomethane permitting recommends that appeals are limited to procedural and legal matters only. 38

7.16. Provide a process for update and change

After permits are issued, ongoing compliance must be established, and a mechanism to alter permits as technology and business cases adapt must be in place.

Once permits have been issued, it will be important to provide a mechanism for updating and changing, or amending, the instrument. This is particularly needed because site optimisation is an ongoing process of capital infrastructure changes and modernisation; feedstocks change over time as business dynamics shift; and off-take for energy also changes as the markets for clean energy evolve. Site modifications are inevitably part of the equation.

Clear guidance must, therefore, be provided on what changes will trigger an update. Examples of changes that usually warrant updates are core changes to technology, acceptance of a different class of feedstocks, or alterations to the facility processing capacity.

The regulator can revise and update standard rule permits and exemptions at a central point. For other permit types an application process may be needed to change conditions.

7.17. Enforce compliance of permits once issued

Establish methods for assessing operator compliance with permits once issued. This can be through a combination of activities such as site visits and inspections, and operator submissions and reporting. Take a risk-based approach towards monitoring compliance with greater regulatory attention paid to sites that are higher risk due to plant location, scale, design and performance, and compliance history.

To minimise regulatory burden, this is most efficiently accomplished by providing a single regulator for all environmental permitting aspects.

It is important to have regulations to provide the regulator with the necessary powers to enforce permits, and codes of practice on how to perform these duties. It is also important for those powers to be clear, transparent and unambiguous. Enforcement responses to different levels of non-compliance should be proportionate, consistent, transparent and based on clear policy and guidelines for regulators.

EXAMPLE

The Environment Agency of England has published an enforcement and sanctions policy. 39

The Scottish Environmental Protection Agency has published guidance on its enforcement policy approach. 40

Natural Resources Wales has published an enforcement and sanctions policy 41.

7.18. Looking forward

At present, the biogas industry is driven by key factors such as climate change mitigation, waste management, food security, energy security and the health and well-being of communities – all of which are closely linked to the health of the environment. To fully capitalise on the benefits of biogas production, biogas plants must be designed, developed and operated in a way that prioritises environmental protection.

However, for the biogas industry to grow at the pace required to meet these global challenges, environmental permitting processes must be streamlined and expedited. A more efficient permitting framework would reduce delays, encourage innovation and facilitate the deployment of biogas technologies, while maintaining strong environmental safeguards. This Pillar has outlined several solutions aimed at improving the permitting process. It is now the responsibility of governments to adopt and implement these recommendations, ensuring that biogas development aligns with both environmental protection and the broader goals of sustainability.

FOOTNOTES

- EPA EcoBox Tools by Exposure Pathways – Exposure Pathways In ERA, US EPA. https://www.epa.gov/ecobox/epa-ecobox-tools-exposure-pathways-exposure-pathways-era.

- Risk assessments for your environmental permit, UK Government. https://www.gov.uk/guidance/risk-assessments-for-your-environmental-permit.

- LCRM: Stage 1 risk assessment, UK Government. https://www.gov.uk/government/publications/land-contamination-risk-management-lcrm/lcrm-stage-1-risk-assessment.

- Accelerating Biomethane Permitting, Biomethane Industrial Partnership. https://bip-europe.eu/wp-content/uploads/2023/10/BIP_Task-Force-2_Accelerating-biomethane-permitting_Oct2023.pdf.

- Short-, Mid- and Long-Term Strategies to Speed Up Biomethane Deployment in Europe, European Biogas Association. https://www.europeanbiogas.eu/wp-content/uploads/2022/06/Short-mid-and-long-term-strategies-to-speed-up-biomethane-deployment-in-Europe.pdf.

- The zoning map can be found at https://gis.columbus.gov/zoning/.

- Siting of Large-Scale Renewable Energy Projects, US Department of Energy. https://www.energy.gov/eere/siting-large-scale-renewable-energy-projects.

- Urban Planning Code, French Government, https://www.legifrance.gouv.fr/codes/texte_lc/LEGITEXT000006074075/2023-09-30.

- EU to Speed Up Permitting Process for Renewable Energy Projects, Council of the EU. https://www.consilium.europa.eu/en/press/press-releases/2022/11/24/eu-to-speed-up-permitting-process-for-renewable-energy-projects/pdf.

- Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on Waste and Repealing Certain Directives. https://www.legislation.gov.uk/eudr/2008/98/contents#

- Regulation (EC) No 1069/2009 of the European Parliament and of the Council of 21 October 2009 Laying Down Health Rules as Regards Animal By-Products and Derived Products not Intended for Human Consumption. http://data.europa.eu/eli/reg/2009/1069/oj

- Anaerobic Digestion, Government of Ontario. https://www.ontario.ca/page/anaerobic-digestion#section-1.

- Directive (EU) 2015/2193 of the European Parliament and of the Council of 25 November 2015 on the Limitation of Emissions of Certain Pollutants into the Air from Medium Combustion Plants. http://data.europa.eu/eli/dir/2015/2193/oj.

- Medium Combustion Plant: When You Need a Permit, UK Government. https://www.gov.uk/guidance/medium-combustion-plant-when-you-need-a-permit.

- Regulation (EU) 2019/1009 of the European Parliament and of the Council of 5 June 2019 Laying Down Rules on the Making Available on the Market of EU Fertilising Products. http://data.europa.eu/eli/reg/2019/1009/oj

- Design of Containment Systems for the Prevention of Water Pollution from Industrial Incident, CIRIA. https://www.ciria.org/CIRIA/Resources/Free_publications/containment_systems.aspx